Petrofac transforms large-scale building with Azure IoT

Determine 1. Petrofac is a number one oilfield companies firm

Petrofac unlocks worth for vitality clients

Petrofac, designs, builds, operates, and maintains oil, gasoline, and renewable vitality property. The corporate is dedicated to digital transformation. It seems to unlock worth for itself and its purchasers utilizing applied sciences like synthetic intelligence (AI), Web of Issues (IoT), automation, machine studying, predictive analytics, digital twin, and Edge computing.

“That is an thrilling time for Petrofac,” explains Fady Sleiman, Chief Digital Officer, Petrofac. “We’re working to include digital platforms inside our enterprise and mix these with our engineering and operations know-how to underpin our competitiveness within the market and enhance {our capability} and effectiveness.”

Partnering to rework large-scale building

When contemplating the impression of digital know-how inside its building actions Petrofac turned to Accenture Digital’s Business X.Zero staff to create an answer that might enhance security, productiveness, and effectivity at its venture websites in the course of the crucial building and commissioning phases.

Petrofac’s venture supervisors have to reply questions like, “Are my welders effectively distributed on obtainable work-fronts at present?” or “Has my concrete mixer arrived?” or ‘’Do we’ve got sufficient security supervision on the boiler’s space?’’ on tasks which might be unfold out over the dimensions of a giant metropolis involving 1000’s of individuals, a whole lot of tons of supplies, and heavy tools motion. Accenture Digital labored with Petrofac to develop a Linked Building answer utilizing Azure IoT to supply these insights.

“Azure IoT enabled us to construct out an answer with Edge analytics and PaaS cloud parts. These had been instrumented utilizing a spread of connectivity options to allow us to fulfill the size necessities for the venture,” mentioned Yen-Sze Quickly, Managing Director, Accenture Digital – Business X.0.

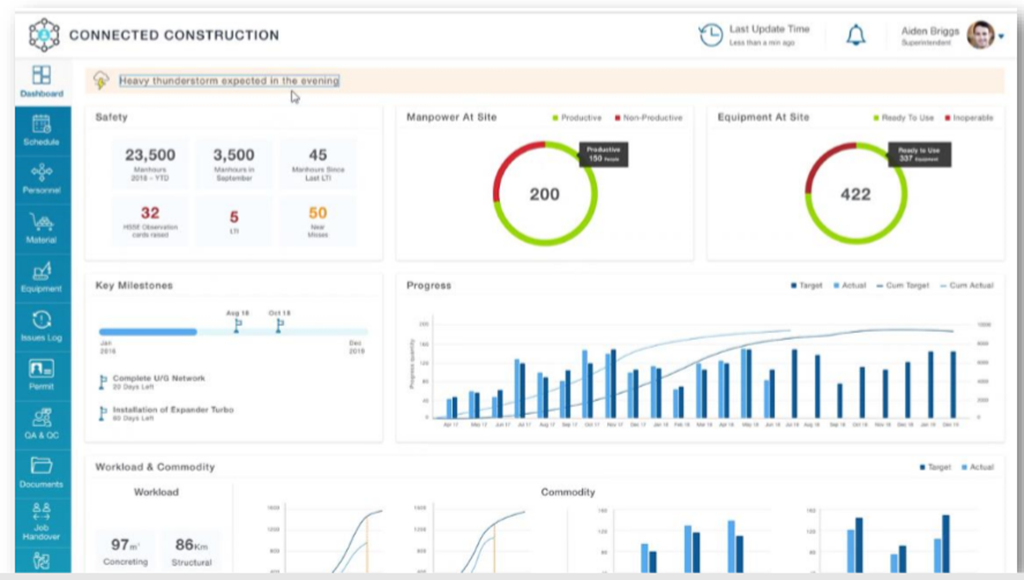

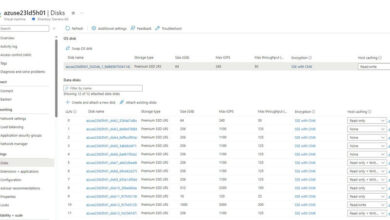

Accenture architected an answer to gather and transmit information from tags on employees and tools. The positioning information was built-in with venture information like milestones, productiveness, planning, allowing, climate, and paperwork in addition to historic information, to supply a stay, one-stop dashboard. The dashboard gives operational visibility into exact particulars of the venture, all accessed in a single place (see Determine 2.)

“The stay dashboard shows venture KPIs, construct progress, whole variety of individuals and tools on website, and climate alerts. It even flags deviations schedule and deliberate manufacturing compliance,” mentioned Daniel Atbir, Vice President, Building, Petrofac.

Determine 2. An instance of the one-stop view of a building venture

Mission monitoring to extend productiveness

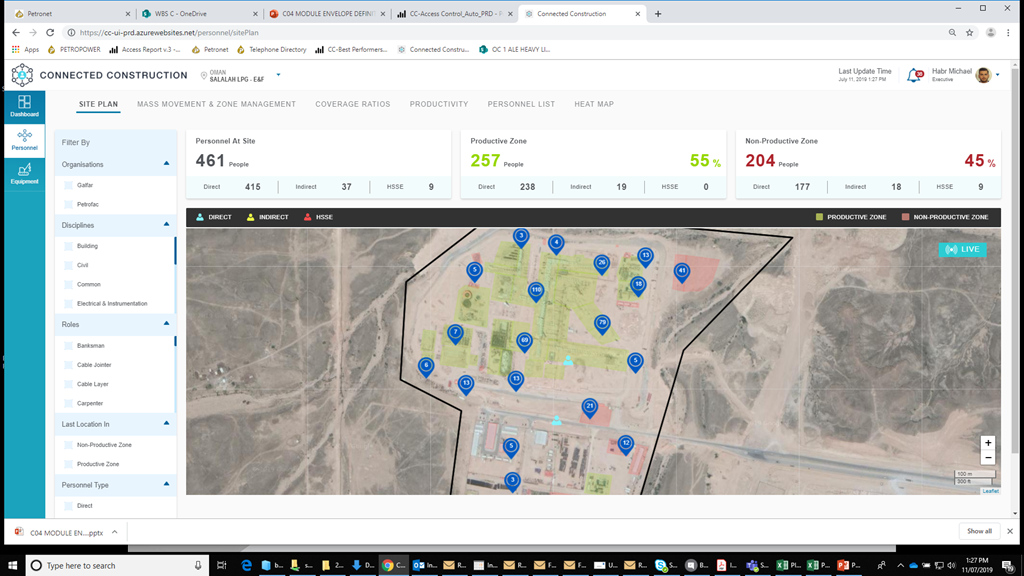

With the brand new dashboard, website supervisors monitor productiveness throughout building zones or inside building crews (See Determine 3.) They will pinpoint bottlenecks and deviations and take applicable remedial motion.

Through the preliminary trial, the staff noticed that productiveness dropped considerably earlier than and after lunch. Wanting on the employee heatmap, the staff realized that productiveness was slowing down as a result of employees had been leaving the development website. They had been driving a distance to get lunch. Petrofac responded by constructing an onsite cafeteria. Productiveness and welfare elevated.

Determine 3. An instance of a map of manpower in building zones

Pursuing higher outcomes for employee security

If a employee requires help on the job, she or he can activate an alarm sign on the digital tag every employee wears. The positioning supervisor and well being, security, and atmosphere (HSE) staff receives the alert and might present rapid help. “With real-time alerts and figuring out the employee’s actual location, our groups reply extra shortly for higher outcomes,” explains Daniel.

Optimizing the usage of high-value tools

Figuring out the situation of apparatus appears easy. However on a large-scale infrastructure venture, it may be a problem. By tagging high-value tools and having places transmitted and recognized in real-time, Linked Building is enabling Petrofac to assist its subcontractors to optimize the usage of tools in a extra collaborative approach. Gear is optimally allotted to extend productiveness and, due to this fact, building progress.

Determine 4. Petrofac positive factors precious insights from Linked Building

Abstract

Petrofac and Accenture Digital carried out the Linked Building answer on a big scale to extend productiveness, security, and effectivity. Accenture and Avanade gained the Microsoft Web of Issues Associate of the Yr award based mostly on their involvement with the Petrofac venture and dedication to Azure IoT. “Due to Accenture’s trade innovation and the Microsoft Azure IoT platform, our Linked Building initiative is offering precious insights for Petrofac,” added Fady.

Be taught extra about Azure IoT and Azure IoT Edge.