Microsoft companion ANSYS extends means of Azure Digital Twins platform

Digital twins have moved from an thrilling idea to actuality. Extra corporations than ever are connecting belongings and manufacturing networks with sensors and utilizing analytics to optimize operations throughout equipment, crops, and industrial networks. As actual digital representations of the bodily atmosphere, digital twins incorporate historic and real-time knowledge to allow refined spatial evaluation of key relationships. Groups can use digital twins to mannequin the impression of course of modifications earlier than placing them into manufacturing, lowering time, value, and threat.

For the second yr in a row, Gartner has recognized digital twins as one of many prime 10 strategic know-how tendencies. In accordance with Gartner, whereas 13 % of organizations which are implementing IoT have already adopted digital twins, 62 % are within the course of or plan to take action. Gartner predicts a tipping level in 2022 when two out of three corporations could have deployed not less than one digital twin to optimize some side of their enterprise processes.

That is why we’re excited by the nice work of ANSYS, a Microsoft companion working to increase the worth of the Microsoft Azure Digital Twins platform for our joint clients. The ANSYS Twin Builder combines the ability of physics-based simulations and analytics-driven digital twins to supply real-time knowledge switch, reusable elements, ultrafast modeling, and different instruments that allow groups to carry out myriad “what-if” analyses, and construct, validate, and deploy complicated methods extra simply.

“Collaborating with ANSYS to create a sophisticated IoT digital twins framework gives our clients with an unprecedented understanding of their deployed belongings’ efficiency by leveraging physics and simulation-based analytics.” — Sam George, company vice chairman of Azure IoT, Microsoft

Digital twins mannequin key relationships, simplifying design

Digital twins can be first and most generally adopted in manufacturing, as industrial corporations make investments thousands and thousands to construct, preserve, and monitor the efficiency of remotely deployed IoT-enabled belongings, equipment, and autos. Operators depend upon near-continuous asset uptime to attain manufacturing targets, which means supply-chain bottlenecks, machine failures, or different sudden downtime can hamper manufacturing output and scale back income recognition for the corporate and its clients. The usage of digital twins, analytics, enterprise guidelines, and automation helps corporations keep away from many of those points by guiding decision-making and enabling on the spot knowledgeable motion.

Digital twins can even simulate a multidimensional view of asset efficiency that may be endlessly manipulated and perfected previous to producing new methods or units, ending not simply the guesswork of manually predicting new processes, but in addition the price of growing a number of prototypes. Digital twins, analytics-based instruments, and automation additionally equip corporations to keep away from pointless prices by prioritizing points for funding and backbone.

Digital twins can optimize manufacturing throughout networks

Longer-term, corporations can extra simply function international provide chains, manufacturing networks, and digital ecosystems via the usage of IoT, digital twins, and different instruments. Enterprise groups and their companions will have the ability to pivot from sensing and reacting to modifications to predicting them and responding instantly primarily based on predetermined enterprise guidelines. Utilities can be higher ready to foretell and forestall accidents, corporations poised to deal with infrastructure points earlier than clients complain, and shops extra strategically set as much as preserve sufficient inventories.

Simulations improve digital twins’ effectiveness

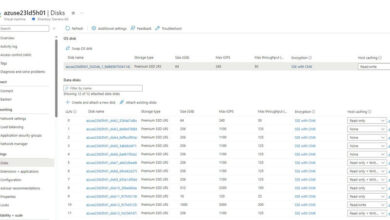

ANSYS’ engineering simulation software program permits clients to mannequin the design of almost each bodily product or course of. The simulations are then compiled into runtime modules that may execute in a docker container and combine routinely into IoT processing methods, lowering the heavy raise of IoT customization.

With the mixed Microsoft Azure Digital Twins-ANSYS physics-based simulation capabilities, clients can now:

- Simulate baseline and failure knowledge leading to correct, physics-based digital twins fashions.

- Use physics-based predictive fashions to extend accuracy and enhance ROI from predictive upkeep applications.

- Leverage “what-if analyses” to simulate completely different options earlier than selecting the right one.

- Use digital sensors to estimate important portions via simulation.

As well as, corporations can use physics-based simulations throughout the Microsoft-ANSYS platform to pursue high-value use circumstances reminiscent of these:

- Optimize asset efficiency: Groups can use digital twins to mannequin asset efficiency to guage present efficiency versus targets, figuring out, resolving, and prioritizing points for decision primarily based on the worth they create.

- Handle methods throughout their lifecycle: Groups can take a methods method to managing complicated and dear belongings, driving throughput and retiring methods on the superb time to keep away from over-investing in market-lagging capabilities.

- Carry out predictive upkeep: Groups can use analytics to find out and schedule upkeep, scale back unplanned downtime and dear break-fix repairs, and carry out repairs so as of significance, which frees group members from pointless work.

- Orchestrate methods: Firms will finally create methods of intelligence by linking their gear, methods, and networks to orchestrate manufacturing throughout crops, campuses, and areas, attaining new ranges of visibility and effectivity.

- Gas product innovation: With speedy digital prototyping, groups will have the ability to discover myriad product variations, lowering the time and value required to innovate merchandise, lowering product failures, and enabling the event of personalized merchandise.

- Improve worker coaching: Firms can use digital twins to conduct coaching with workers, enhancing their effectiveness on the job whereas lowering manufacturing design errors attributable to human error.

- Get rid of bodily constraints: Digital twins get rid of the bodily obstacles to experimentation, which means customers can simulate exams and circumstances for distant belongings, reminiscent of gear in different crops, areas, or house.

Opening up new alternatives for companions

In accordance with Gartner, greater than 20 billion linked units are projected by 2020 and adoption of IoT and digital twins is simply going to speed up—in truth, MarketsandMarkets™ estimates that the digital twins market will attain a price of $3.eight billion in 2019 and develop to $35.eight billion by 2025. Our current IoT Alerts analysis discovered that 85 % of decision-makers have already adopted IoT, 74 % have initiatives within the “use” part, and companies anticipate to attain 30 % ROI on their IoT initiatives going ahead. The highest use case individuals need to pursue is operations optimization (56 %), to reap extra worth from the belongings and processes they already possess. That’s why digital twins is so essential proper now as a result of it gives a framework to perform this purpose with better accuracy than was doable earlier than.

“As industrial corporations require complete subject knowledge and actionable insights to additional optimize deployed asset efficiency, ecosystem companions should collaborate to kind enterprise options. ANSYS Twins Builder’s complementary simulation knowledge stream augments Azure IoT Providers and enormously enhances its clients’ understanding of asset efficiency.”—Eric Bantegnie, vice chairman and common supervisor at ANSYS

Due to Microsoft companions like ANSYS, corporations are higher geared up to unlock productiveness and effectivity beneficial properties by eradicating important constraints, together with bodily obstacles, from course of modeling. With instruments like digital twins, corporations can be restricted solely by their very own creativity, making a extra clever and linked world the place all have extra alternatives to flourish.

Study extra about Microsoft Azure Digital Twins and ANSYS Twin Builder.